Lorem ipsum dolor sit amet, consectetur

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

OCIMF SIRE 2.0 questionnaire set KPIs for verification of MEG4 compliances

1st Jan 2024 SOLAS Amendments mandated ships to follow thorough Design, Maintenance & Inspection Rules

Numerous Ports in Australia, South America & other locations adopting more stringent guidelines than SOLAS & MEG4

OCIMF published fourth edition of Mooring Equipment Guidelines

Rightship included MEG4 guidelines as a reference point for inspections

Class to verify SOLAS compliances in their inspections

How to calculate SDMBL, evaluate SWL of fittings etc?

Ensuring individual guidelines are met as per the trading area

Line Management, Mooring Fittings Management usage & lifecycle record keeping

Needs to be Manufacturer specific, fit for intended Vessel service, design etc.

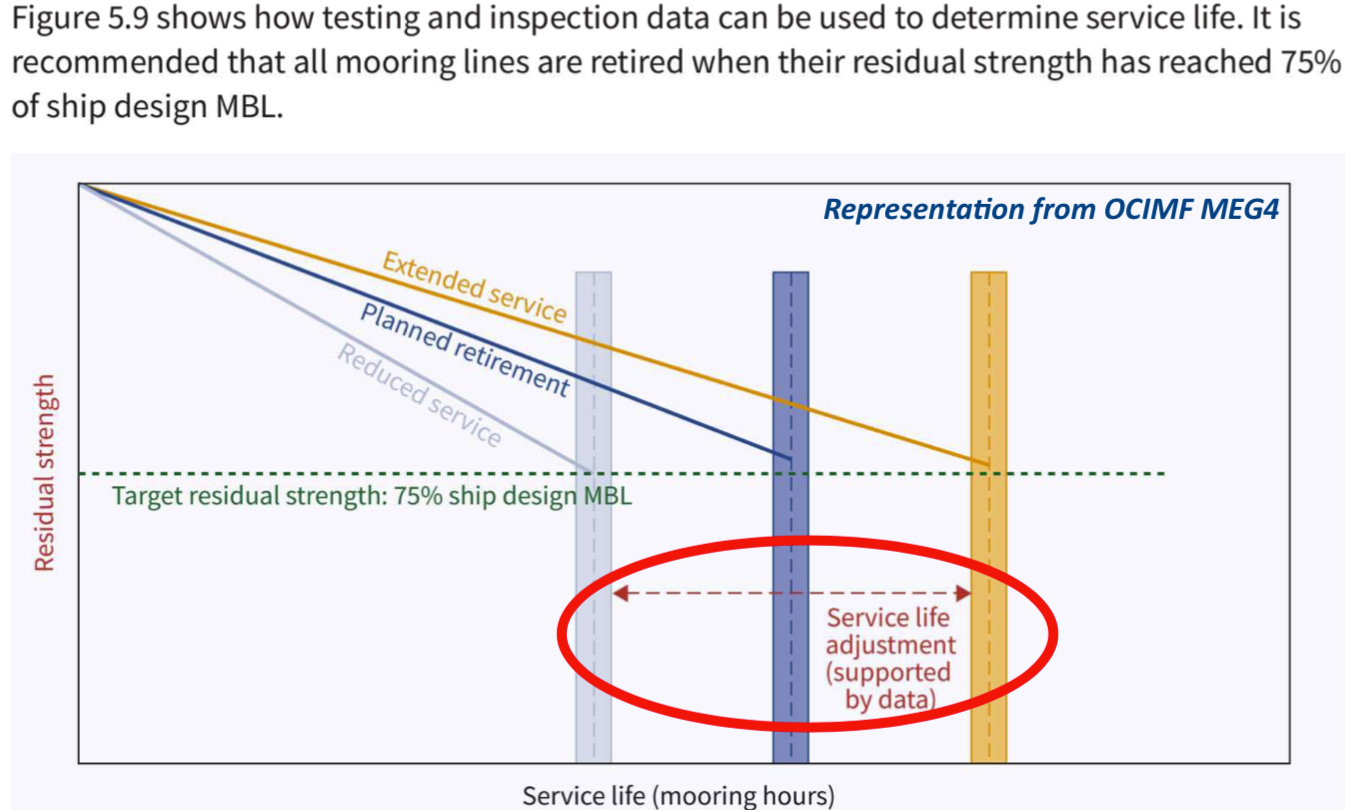

Making informed data supported decisions

Service life, quality, cost & availability data comparisons

Digimoor X7 helps Ship Owners make data-supported decisions of planning Rope retirement & preventing possible snapping in use

This versatile software fully complies with OCMIF Mooring Equipment Guidelines (MEG4), TMSA 3 and upcoming SOLAS regulations.

The software is ‘Simple to use yet intelligently collects all the required data’. The user interface is intuitive & Seafarer-friendly.

DigiMoor X7 uses Artificial Intelligence ML based algorithms to predict residual strength of non-tested ropes based on samples tested

DigiMoor X7 uses Artificial Intelligence ML based algorithms to predict residual strength of non-tested ropes based on samples tested

It is intelligently programmed to help seafarers remain objective in their decision-making approach through data-backed insights

Comparative analysis of fleet-wide maker’s & rope type cost per running hour for each trade pattern

DigiMoor X7 complies to latest Cyber security guidelines & is also GDPR compliant

Digimoor X7 helps Ship Owners make data-supported decisions of planning Rope retirement & preventing possible snapping in use

This versatile software fully complies with OCMIF Mooring Equipment Guidelines (MEG4), TMSA 3 and upcoming SOLAS regulations.

The software is ‘Simple to use yet intelligently collects all the required data’. The user interface is intuitive & Seafarer-friendly.

DigiMoor X7 uses Artificial Intelligence ML based algorithms to predict residual strength of non-tested ropes based on samples tested

DigiMoor X7 uses Artificial Intelligence ML based algorithms to predict residual strength of non-tested ropes based on samples tested

It is intelligently programmed to help seafarers remain objective in their decision-making approach through data-backed insights

Comparative analysis of fleet-wide maker’s & rope type cost per running hour for each trade pattern

DigiMoor X7 complies to latest Cyber security guidelines & is also GDPR compliant

Even if you are already using a software for mooring system management, you can’t ignore DigiMoor X7!

Your Vessel was designed Pre-MEG4 and you currently do not have precise calculations to determine her SDMBL. Our expert team has completed SDMBL calculations (as per MEG4 Section 3) for more than 250 Ships and can swiftly complete one for you. We have completed these for LNG, LPG, VLCC, Oil, Chemicals, Bulk, Containers and Car Carriers. Undoubtedly, we are the industry leaders in calculation of Ship Design MBL for existing ships. We follow an OCIMF MEG4 approved methodology to conduct these calculations, which are well accepted by Inspectors.

MEG4 states your Mooring fittings Safe Working Load (SWL) shall be equal to or more than the Ship Design MBL (SDMBL). In case your Vessel fittings have lower SWL than SDMBL, our experts can help you prepare an engineering assessment and a Gap analysis Study. In most cases, the Vessel does not require any design modifications*. In addition, we hold expertise in GAP Analysis Study w.r.t your procedures compliance with OCIMF MEG4, SIRE 2.0, TMSA, RIGHTSHIP, DBMS and Upcoming SOLAS Regulations (MSC Circular 1620 and 1175).

5.4.2 Line Management Plan requires ‘Detailed Inspection’ to be conducted by Manufacturer’s representative, third party expert or ship personnel. Our Experts have been trained on all types of Lines be it HMPE, Synthetics, Nylon or Wires. In addition, being Seafarers, we are also trained for thoroughly inspecting Mooring Equipments. ALL are boarding teams hold requisite competence to conduct onboard inspections. On a normal routine, we conduct such inspections on more than 200 vessels an year. Contact us for best quotes for your full fleet.

We hold an experience of drafting Mooring System Management Plan, Line Management Plan, MSMPR & LMPR for more than 400 vessels. The plans that we draft cover complete aspects and guidelines of OCIMF MEG4, SIRE 2.0, TMSA, RIGHTSHIP, DBMS and Upcoming SOLAS Regulations (MSC Circular 1620 and 1175). We keep ourselves aware of latest Inspection Observations in the industry and ensure our teams deliver the most upto date plans to our clients. We deliver ‘Ship-specific’ plans which are ‘to the point’ and easily communicated to the Seafarers.

A major change that happened with OCIMF MEG4 was that it mentioned that you need to Discard the Rope when its Residual Strength reaches 75% or below, of Ship Design MBL. Current innovations only allow the Residual Strength to be verified through a destructive test conducted at an approved Testing Facility. Our team offers end-to-end solution for Ship Owners & Managers, to co-ordinate, instruct, board ships (if required) and send the ropes ashore for Residual Strength testing. We have a large ‘World-wide’ network to cover your Fleet requirements through a single-point solution.

We have an expert team available World-wide to attend ALL your Fleet Vessels through a single point of contact. Our systems are well-designed to give you the same experience for all types of vessels trading in any region of the World. Our experts are trained to handle most modern types of Rope for their Splicing, Cropping, Damage repairs including Jacketed or Unjacketed ropes. We are certified by most Rope Makers to conduct these tasks and attend Vessels on their behalf. We are the MOST “pocket-friendly” service available across the World.